Introduction

Welcome to a comprehensive exploration of how decarbonization starts with manufacturing strategies. In an era where environmental concerns are paramount, industries play a crucial role in reducing carbon emissions to mitigate the effects of climate change. Decarbonization, the process of eliminating carbon emissions, is a global initiative that requires a concerted effort from manufacturers worldwide.

This article will delve into the intricate relationship between manufacturing strategies and carbon reduction. We will discuss various innovative approaches, technologies, and best practices adopted by industries to align their operations with sustainability goals. Whether you’re a manufacturer, a concerned citizen, or an environmental enthusiast, this article aims to provide valuable insights into decarbonization and its significance in creating a sustainable future.

Decarbonization Starts with Manufacturing Strategies

Manufacturing, being a significant contributor to greenhouse gas emissions, holds a unique position in the fight against climate change. Embracing sustainable practices in the manufacturing sector is paramount to achieve global decarbonization goals. Let’s explore some key strategies that manufacturers can adopt to kickstart their decarbonization journey.

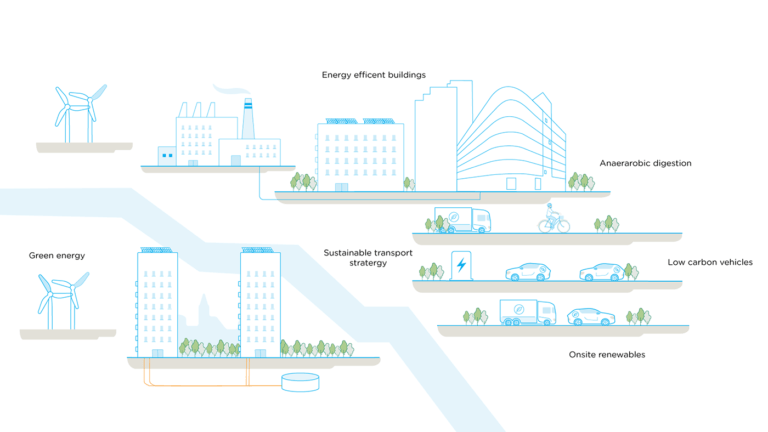

1. Embracing Renewable Energy Sources

Transitioning from fossil fuel-based energy to renewable sources is a crucial step for manufacturers looking to reduce their carbon footprint. Solar, wind, hydroelectric, and geothermal energy offer cleaner alternatives that can power production processes sustainably.

2. Energy-Efficient Manufacturing Techniques

Implementing energy-efficient technologies, such as LED lighting, advanced automation systems, and smart controls, can significantly decrease energy consumption during manufacturing operations.

3. Circular Economy Principles

Adopting circular economy principles, where products and materials are recycled and repurposed, minimizes waste generation and promotes a sustainable, closed-loop system.

4. Optimize Supply Chain Logistics

Streamlining supply chain logistics reduces transportation-related emissions. Leveraging data analytics and innovative transportation methods can lead to cost-effective and eco-friendly solutions.

5. Carbon Capture and Storage (CCS)

Investing in CCS technologies enables manufacturers to capture carbon dioxide emissions and store them underground, preventing their release into the atmosphere.

6. Material Substitution

Exploring alternative materials with a lower carbon footprint can have a substantial impact on reducing emissions during the manufacturing process.

7. Collaborative Industry Initiatives

Participating in industry-wide initiatives and partnerships allows manufacturers to share best practices, pool resources, and collectively work towards decarbonization.

8. Employee Training and Awareness

Educating employees about the importance of decarbonization and involving them in sustainability efforts can foster a culture of environmental responsibility within the organization.

9. Government Incentives and Policies

Manufacturers can take advantage of government incentives and policies aimed at promoting green practices and sustainable manufacturing.

10. Life Cycle Assessment (LCA)

Conducting an LCA of products helps identify areas of improvement in the supply chain and manufacturing process, leading to more sustainable product design and production.

11. Water Conservation Measures

Implementing water conservation measures not only reduces water usage but also the energy required for water treatment and transportation.

12. Green Building and Facility Design

Constructing green buildings and adopting sustainable facility designs can significantly decrease energy consumption and emissions.

13. Decentralized Manufacturing

Encouraging localized production can reduce transportation needs and minimize the carbon impact associated with long-distance logistics.

14. Lean Manufacturing Principles

Implementing lean manufacturing practices improves operational efficiency, reduces waste, and subsequently lowers carbon emissions.

15. Setting Ambitious Decarbonization Goals

Establishing clear and ambitious decarbonization targets ensures that manufacturers stay committed to sustainability and regularly measure their progress.

16. Public-Private Partnerships

Collaborating with governments, NGOs, and other stakeholders fosters innovation and accelerates the implementation of sustainable manufacturing practices.

17. Industry 4.0 and Internet of Things (IoT)

Leveraging Industry 4.0 technologies and IoT enables predictive maintenance, optimized resource utilization, and overall more sustainable operations.

18. Sustainable Packaging Solutions

Incorporating eco-friendly packaging materials and designs helps reduce waste and environmental impact throughout the product’s life cycle.

19. Green Certifications and Labels

Seeking green certifications and labels for products highlights a manufacturer’s commitment to sustainability and attracts environmentally conscious consumers.

20. Research and Development

Investing in R&D for cleaner technologies and sustainable materials paves the way for future innovations in decarbonization.

21. Carbon Pricing Mechanisms

Supporting and advocating for carbon pricing mechanisms encourages a shift towards low-carbon production practices.

22. Transparent Reporting and Accountability

Practicing transparent reporting on carbon emissions and sustainability initiatives keeps manufacturers accountable for their environmental impact.

23. Continuous Improvement

Sustainable manufacturing is an evolving process. Manufacturers should continuously seek ways to improve and innovate their decarbonization strategies.

24. Engaging with Local Communities

Collaborating with local communities fosters a shared commitment to sustainability and ensures that manufacturing activities align with community needs.

25. Sustainable Sourcing

Sourcing raw materials from suppliers committed to sustainability further extends a manufacturer’s environmental responsibility.

FAQs

Q: How does decarbonization benefit the manufacturing sector?

Decarbonization offers several benefits to the manufacturing sector. By adopting sustainable practices, manufacturers can reduce operational costs, enhance their brand reputation, access new markets driven by green preferences, and ensure regulatory compliance.

Q: What challenges do manufacturers face during decarbonization?

Manufacturers may encounter challenges like initial capital investment for sustainable technologies, the need for workforce upskilling, and integrating sustainability into existing processes. However, overcoming these challenges leads to long-term environmental and economic advantages.

Q: Can small and medium-sized manufacturers contribute to decarbonization effectively?

Absolutely! While large-scale manufacturers have a substantial impact, small and medium-sized manufacturers can contribute significantly by adopting energy-efficient technologies, sustainable sourcing, and circular economy principles.

Q: How can governments support decarbonization efforts in the manufacturing sector?

Governments can support decarbonization by providing financial incentives, offering grants for R&D, creating supportive policies, and facilitating public-private partnerships to foster innovation and knowledge sharing.

Q: Does decarbonization compromise manufacturing efficiency?

On the contrary, decarbonization can improve manufacturing efficiency by reducing waste, optimizing resource utilization, and implementing lean practices. Sustainable manufacturing often leads to greater operational efficiency.

Q: Is it possible for manufacturers to achieve carbon neutrality?

While achieving absolute carbon neutrality may be challenging, manufacturers can significantly reduce their carbon emissions through a combination of sustainable practices and carbon offset initiatives.

Conclusion

Decarbonization starts with manufacturing strategies, and it is a shared responsibility of industries and society to create a sustainable future. By adopting renewable energy, optimizing operations, embracing circular economy principles, and collaborating with stakeholders, manufacturers can lead the way in mitigating climate change. The journey towards decarbonization may present challenges, but with innovation, collaboration, and commitment, a greener and more sustainable manufacturing sector is within reach.

So, whether you’re a manufacturer looking to make a positive impact or an advocate for a cleaner planet, remember that decarbonization is not just an option – it’s a necessity for the well-being of our planet and future generations.